BY ARMEN AMIRIAN from Motorcycle Road Racer illustrated/November 88

FOLLOWING THE DOCTOR'S ORDERS:

The Making of the Mandello Missile

What if you were a doctor looking for some nifty new equipment for a long and difficult operation? You'd probably opt for the latest high-tech, top-shelf, whizmo-gizmo stuff from a well- known major manufacturer. Wouldn't you? You certainly wouldn't go for the most obscure stuff around, made by a small but reputable old firm that sells so few of its products that it doesn't even have a calculable market share? Not likely. Add to the decision the fact that the machine was more than a bit outdated and that you would have to do all of the updating and customizing of said old clunker yourself, with only minimal outside assistance.

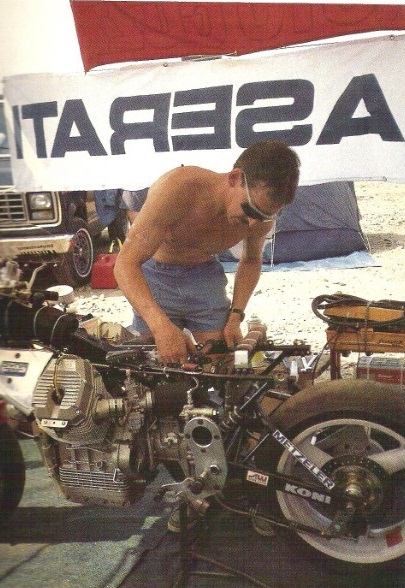

If you were were Dr. John Wittner, the choice would be obvious go for the old and odd. You see, although he is a doctor (a dentist, actually) a tent propped up behind an old van is his new doctor's office, the operating room he concerns himself with now is a road race track, his surgical implements are Snap-On tools, and his trusted assistant is ace road racer Doug Brauneck. The goal of the operation is to extract the Number One plate from the hotly-contested Pro Twins Grand Prix class. For Dr. John, the right machine is a thundering 1000cc V-twin Moto-Guzzi.

THE DOCTOR

Wittner is a gearhead from way back. His interest in machines led him to all sorts of tinkering and even a few mechanical engineering classes. Then came a letter from Uncle Sam and a tour of Vietnam. Somehow, after he got out of the service, John Wittner became Dr. John, tuner of teeth. After a few years of modifying molars, the Doc decided to come out and admit that all along he had been a closet gearhead. After trying a few paths, he found that endurance racing Moto Guzzi was what he wanted to do. To a casual observer, the idea of some dentist making a competitive racer out of a Guzzi was akin to a blind man in a dark cellar looking for a black cat that wasn't there. But build he did, and victory they achieved. For two years in a row (1984-85), the Dr. John's Moto-Guzzi held the number one plate in endurance road racing; all the while a strictly privateer effort funded entirely by the good doctor. Buoyed by his success and aspiring to broaden his horizons, Dr. John decided to bring the bike to the prestigious Isle of Man TT races. This would give him and his bike international exposure.

The first part of 1986 was spent building a bike for the Island. By the time the TT in June rolled around, the Doc was beyond broke. He'd sold everything he had in order to go racing, and desperately needed to do well at the TT. alas, there was no happy ending to the fairy tale, The boat carrying the race bike took a detour and didn't get to the races in time. The project was a complete loss.

SECOND OPINION

Realizing that the Guzzi was no longer competitive against the megahorsepower four-cylinder Japanese

bikes in endurance races, the Doctor looked for a new class to race in. After some figuring, he decided that he could build a competitive sprint-race motor out of a Guzzi and race it in the Battle of the Twins (later renamed Pro Twins)

Grand Prix class. He convinced the boys at Guzzi to give him some parts and disappeared into his workshop. By the winter of '86, Wittner had an engine that he thought could be competitive, and he designed and built. an innovative monoshock chassis that was both lighter and stronger than the stock one. He started planning a race team.

As usual, the team was a shoestring effort, but there was some sponsorship, including donations from the loyal and enthusiastic members of the Moto-Guzzi National Owner's Club. As opposed to the group efforts of the endurance racing days, this was a much more compact team. Dr. John. became the designer, fabricator, machinist, welder, tuner, grunt, van driver, chief cook and bottle washer. Brauneck became the main rider, the backup rider, the suspension development team, the mechanical consultant and the confessor. This team was definitely the underdog. However, in

the best tradition of adventure movies, the daring duo managed to win the series, not crash too much, and still retain the desire to race again.

THE LAB ASSISTANT

To understand why Dr. John calls his rider "Bionic Brauneck," one only has to watch the boys at the track. At Loudon, New Hampshire, the temperature and humidity hovered around 100. Brauneck climbed into his leathers and cut some fast practice laps on the Guzzi, then rode into the pits, traded his perspiration-soaked Guzzi leathers for the Yamaha ones, and climbed onto the John Hasty Racing Yamaha TZ250 he also campaigns. A few laps on the Yamaha, and back in again.

While peeling off his leathers, he calmly told both Dr. John and Mr. John what was working and what wasn't on both bikes. The only similarities.

between the 360 pound, 110-plus hp. air-cooled, four-stroke Guzzi and the 230 pound, 70-odd hp, water-cooled, two-stroke Yamaha are that they both have wheels and shift on the left side.

To be able to make the transition that fast and record mental notes on their respective performances is amazing.

Brauneck also campaigns a Suzuki GSXR for Team Lockhart in the endurance races. Here, again, is the quiet. seriousness of a mafia hit man. For a man of his talents, he is amazingly modest and easygoing. Witness that his Lockhart teammate is none other than Dale Quarterley, his chief rival in the Pro Twins series. When Quarterley crashed the Lockhart bike in the first turn at Loudon (ending Doug's ride before it started), "Bionic" just gave his shoulders a "That's racing" shrug and headed off to see if Dale was hurt.

THE SYMPTOMS

For 1988, something had to change. The old two-valve motor had been leaned on about as hard as possible. Using a short-stroke crank from an old 750 and a set of Manfred Hecht(aka Raceco USA) massaged 750 heads (favored for their increased port velocity, produced by smaller ports and valves), the bike managed to produce 107 hp and rev to 10,000 rpm, though it was stressed to within an inch of its life. With much work, the 750 heads flowed 128 cubic-feet-per-minute of air (at 10 inches of water), which is much more than the stock 1000cc heads did. To let in that much air at those revs, the valves had to be opened and closed hard and fast. Valve spring pressure reached 140 psi, fatiguing the springs. so much that they were changed each time the bike was run. The practical limit of the two-valve heads had been. reached.

The yearning for high revs is understandable. Simply put, time is a set quantity, engine rpm isn't. Power is produced only during an engine's power stroke. Therefore, to produce more power (from a set displacement) there must be more power strokes. which means more revolutions of the crankshaft (rpm).

Assuming the crankshaft and cases are strong enough, the two biggest problems arising from drastically increasing the rev limit are the practical limits of piston speed and the loads on the valve train caused by bashing open the (relatively large and heavy) valves so fast and banging them shut with strong valve springs. The short-stroke crank kept the piston speed within safe limits, so all that stood in the way of high revs were the heads.

ADD TWO VALVES AND CALL ME IN THE MORNING

The solution was to add more valves. Two small valves can flow more air than one large one, and each uses lighter springs. Moto-Guzzi was already selling a four-valve-per-cylinder 650, but it was still a pushrod operated valve train. Dr. John wanted to eliminate the pushrods. (As he put it, "The only thing wrong with a pushrod motor are the pushrods.") The folks at Mandello del Lario (the factory headquarters) listened and, more surprisingly, acted. A true overhead- cam design would mean having a timing belt or chain (and its cover) run in front of the cylinder head. But, considering that the exhaust side of the head is the hottest part of the engine, blocking off its supply of cooling air in any way was deemed unacceptable. Twin header pipes for each head were also considered and vetoed due to concerns about head overheating caused by blocked airflow.

A compromise solution was found.

The crank would turn a jackshaft (located in the old camshaft location in the base of the "V" between the cylinders), which would then turn camshafts (by way of Gilmer belts) in the new four-valve heads. The "in-head" cams (one in each head) would lift lifters and then rock forked (one finger for each valve) rocker arms. Quite a lot of metal to move to lift a valve, but all simple pieces of sturdy metal (no pushrods to flex under load). Opel used this system successfully in the late 60s on their 1.5-liter Kadett engines.

Guzzi made a four-valve pentroof head with an unfashionably wide 44- degree included angle. The narrow included valve angles favored by the latest Japanese heads coupled with the Guzzi's 3.75-inch bore would have produced a combustion chamber shaped like a trash can lid (wide and flat), making complete combustion. difficult. The new heads showed up just days before Daytona and worked as planned: the new 34mm intake valves of the four-valve head weigh much less than the 44mm valves in the old two-valve motor, requiring only 90-pound springs to control them. Coupled with the elimination of pushrods in the valve train, the new engine revs safely beyond 10,000 rpm

With only two days to assemble and sort out the engine, it ran well enough to take Brauneck to third at Daytona. Wittner took the heads to Raceco in Brooklyn, New York, and spent days working with Hecht and his flow bench. Grinding here, building up there, and checking the results each time on the flow bench, they came up with new port designs that flowed. significantly more. The modified heads were shipped off to Italy where wooden copies were made, molds fabricated, heads cast, and seats and guides installed all in 35 days. The new heads flowed 155 cfm of air a 20 percent improvement over the modi- fied two-valve motor yet they both feel that figure can be improved.

What's more, the casting is one that can easily be mass-produced. Undoubtedly, a nice towershaft gear-driven OHC system would have been more efficient, but it would also have been impractical on a production basis. The whole point of this racing/ development program is to produce a new-generation street bike. Also, this top end could be mounted on a lightly- modified stock crankcase. The major changes to the crankcases were to remove the cylinder studs, bore bigger holes in the cases (for a larger diameter cylinder), build up a little weld around the crankcase holes, and relocate the studs. With the shorter (70mm) stroke of the 750 crank, a huge 95.25mm bore had to be used to produce a 1000cc displacement. New cylinders were made from Nikasil linings. This thin nickel/silicon "coating" transfers heat better than a thick cast-iron sleeve (which, incidentally, there isn't room shed for), allowing the piston to better shed its heat and not expand as much. With the new cylinders, the piston-to-cylinder wall clearance has been reduced to.0025" (about the thickness. of a human hair), making for better oil control as well.

ALL VITAL SIGNS NORMAL

Actually, the engine is quite mundane. The ignition system consists of a Dyna 'S' ignition telling two Dyna coils when to spark the 12mm Autolite spark plugs. The bike is run with fixed advance (usually 31 degrees). The crankshaft is a stock 750 item rebalanced to 53 percent. The only titanium used is in the valve spring keepers. The valves, solid lifters and Carillo rods are all steel. Crane cams run directly in the heads with no ball bearings or inserts. The pistons are a low-silicon- content aluminum alloy, forged from bar stock by the nice folks at Ross. The rocker arms are investment cast and carburized (a surface-hardening process).

After a DNF at Road Atlanta, caused by a broken rocker-arm support block, new ones were made of nodular iron (as in crankshaft material).

The last weak link in the valve train was the single dowel pin securing the cam sprocket onto the end of the shaft. After a DNF at Loudon, caused by a sheared pin, the gears and shafts were modified to use three pins.

Aside from the top end, probably the trickest parts are the aluminum timing ming gears (which replace a chain and sprockets), and an aluminum flywheel assembly (both made by Transkontinental in Switzerland). The gear drive eliminates any fluctuations in cam timing caused by the camchain whipping around (the stock timing chain does not have a tensioner). The aluminum flywheel weighs 7.8 pounds compared to the 16.13 pounds of the stock boat anchor. The lighter flywheel lets the engine rev faster and makes shifting much cleaner and faster. Doug never uses the clutch to upshift, an impossible feat with the stock flywheel.

DO YOU HAVE A TEMPERATURE?

The Guzzi is air-cooled. Period. On racetracks where bikes are water- cooled, oil-cooled, oil- and water- cooled, the Goose manages to keep its cool with just air passing over its cylinder fins. Most tuners live in fear of racing temperatures cooking the engine oil, reducing its viscosity to the point where it slips past the rings into the combustion chamber and burns. The same thin oil has no film strength and is squeezed out of the crank's plain bearings, allowing premature wear. Many tuners are still using high-dollar specialty oils or heavy-duty straight 40- or 50-weight 'R' oils that are so unstable they must be dumped after each race. A common modification to a racebike is to increase its oil capacity, more oil can absorb more heat. Not so for the Guzzi. It lives on just three quarts of you-can-get-it-at-the- local-gas-station Mobil One synthetic 5/30 oil. The engine was built with tight bearing clearances, and the rings seal so well that no oil can sneak past them. In fact, the bike uses restrictors in the oil feed lines for the heads- John feels there may be too much oil up there. The oil runs at about 270- degrees Fahrenheit, which is way too high for a conventional conventional oil, but just fine for a synthetic. To keep an eye on the engine's temperature, the crankcase is marked with temperature-sensitive crayons which melt at specific temperatures, NICE DEEP BREATHS, NOW, IN, OUT, IN, OUT... The bike currently breathes in through 41mm flat-slide Mikunis (the current fad in racing), though John also has a set of round-slide Mikunis which he hopes will work better. The carbs are run with UNI foam air filters-a blessing considering Brauneck crashed in the dirt during the first lap of the Laguna Seca National. In testing, the bike did not lose even one mph off its top end with these filters. Considering how much dirt and debris are on a racetrack, it's hard to understand why anyone would use velocity stacks (vacuum cleaners). It's easier to clean air filters than to rebuild a top end. After trying all manner of two-into-one, two-into-two and two-into-one-into-two exhaust systems, Dr. John found an answer to his pipe dreams. The exhaust is a two-into-one using short 17" header pipes and a short megaphone exiting to the left under the middle of the chassis. A two-into-two was found to give more top-end power, but the two-into-one's superior low end afforded better lap times. The system is made by EPA cycles, which offers a quieter street version.

DESEGREGATED BRAKES

One day the good doctor awoke proclaiming: "I had a dream. I dreamt that one day my three little stoppers will work together ether in harmony, judged not by the location of their discs, but rather on their ability to contribute to stopping power as a whole. For I have showing how hot a particular area is. For I've been to the tall banks of Daytona, and I have seen what speeds a man is capable of. And I know too well how slow is the chicane. Although I may not ride there with you, I will work to make the bike a better machine to race. Let us believe that the Great Designer put brake calipers on the rear wheels for a purpose, and let us find a way to integrate them into our braking system." Yes sir!

It was a result of this dream that Dr. John cast away the rear brake pedal. Now all three brakes (two huge floating discs chomped by four-piston Brembos up front, and one small disc with a two- piston caliper in the rear) are operated by the handlebar lever. The brake lines go to an adjustable brake- proportioning valve (right out of the MOPAR catalogue) that is set to extract maximum rear braking without wheel lockup. By carefully designing the rear brake's torque-arm geometry, John has built in a bit of "prosquat." With 5.8 inches of rear wheel travel in the Yamaha/Vincent-type monoshock, there is plenty of squat left over for bumps. In addition, to limit brake- induced dive, the front shock has increased compression damping built into the last 45mm of travel.

Now the bike settles down on its suspension when the brakes are applied, rather than do a nose-dive. This is especially important for the Guzzi because of its generous 5.51 inches of front wheel travel (more than some street bikes). A front end that dives reduces the rake, trail and wheelbase, making for a twitchier bike. With this system and a pair of wide MBS Metzeler tires on 17" Marvic rims, Doug can brake hard without losing stability.

HAVE A SEAT, YOU WON'T FEEL A THING Abruptly opening and closing the

throttle on a shaft-driven bike makes the chassis go up and down like the congregation at an Armenian High Mass. The driveshaft turning against the ring gear in the rear drive is the action, the tire on the ground is the resistance, and the rear drive lifting the rear of the bike is the reaction (Thank you, Mr. Newton). There is a similar- but-opposite action with chain-driven bikes they tend to compress the rear suspension on acceleration (unless they have a Leitner ATK modification). Street riders can cope with this because it is not noticeable at street speeds. Racers, however, cannot disregard the phenomena. The Doc- tor's chassis has an articulated rear end which can float about the axis of the axle (thanks to a second 'U' joint by the rear drive.) The rear drive sends its torque reaction to the frame by way of a Heim joint-ended arm. This is similar to the paralever system on the BMW R100GS, but it actually works better because none of the force is transmitted through the suspension.

A LITTLE GAS AND IT'LL BE OVER IN A FLASH

For a team that cut it's teeth on endurance racing, the Pro Twins sprint races seem like a warmup. Until that year, the bike was so reliable that DNF were unheard of. John and Doug how to run the bike in endurance races on the top end is sorted out. They feel that the real test for machinery is a long race, not just a few hot laps. Unfortunately, many of the so-called "endurance" races these days are only a few hours long. Sometimes the greate test of endurance is holding you breath long enough to use the trad side bathrooms...

ELECTIVE SURGERY

A tuner's work is never done. On the major wrinkles are ironed out, time for details. First on the list is trip to the fat farm for a weight lo program in the Liz Taylor league. The bike weighs 360 pounds, which svelte compared to the pondero Ducati 851s, but heavy for an a cooled twin. Just changing light stressed fasteners to aluminum al drilling and milling where mass is needed will save a few pounds. aluminum frame is possible (the g tank is already aluminum). But with one-man development team, reliability and horsepower have to take priority

THE DIAGNOSIS

Considering that Moto-Guzzi sells fewer bikes in one year in the U.S. th Honda sells in one day, this whe project is pretty impressive. And when you consider that Europeans have always considered American hot mechanics to be quaint-but-pleasa bozos, it's even more amazing that the man who owns Maserati (and Moto Guzzi/Benelli) would want an American dentist and his American rider take advantage of good old Americian hot rod technology and know-how become his premier Guzzi development team. After all, Italian bike mechanics supposed to wear red overalls, smoke cigars, gesture wildly with their hands and always refer to the bike as "he or "she." It's also important that they have large quantities of body hair and wear dark glasses. The proper way work on an Italian bike is to run around the paddock screaming "Moron!" a "Mama mia" And one would imagine that anyone who puts in in as ma sleepless nights as Dr. John sho have eyes like a Revlon Rabbit and personal warmth of the Ayatollah. None of this fits Dr. John. He is quite friendly and patient. Hours before race he'll take a few minutes that can't spare to read a competition Autolite plugs and offer advice. What more, when he does take off his Coq Sportiff designer sportswear, obvious that he has no chest hair. Dr. John is a bright, meticulous, technician/tuner with the unusual ability both suggest and to listen (and sense to know who to listen to). John has consulted with experts in the field for every area of the bike ignition, porting, tires, etc. And this is America, where most of the World Champion Grand Prix motorcycle riders have come from in the last few years. And, thanks to Superbike racing, the best four-stroke motorcycle hot rod shops are here. This is the land where good old boys make cast-iron pushrod V-8 Chevys turn 10,000 rpm and put out 500 hp. It's no coincidence that the bore on the Guzzi is 95.25mm that's exactly 3.75", allowing the use of American-made car rings. The pistons, cams, rings, valve springs, head work and custom machine work are all made im the USA. The results speak for themselves. Two Number One plates endurance racing and the Number One plate the first year he tried Pro Twins. The goal is the fulfillment of the time-honored expression, "Racing improves the breed." The Japanese have learned that the way to make the best sport bikes is to make the best Superbikes and let the technology trickle (or, more accurately, flow) down. They have been able to cut the transfer time from racer to street bike to just a year or so. Contrast this with non-Japanese bikes, where the street. bikes take many years to see the improvements the race shop has discovered. BMW made a beautiful OHC Boxer racer (the Rennsport) that ruled the sidecar class, but stopped making sidecar bikes for the street and never made a production OHC twin. It is important to run the kind of races

that most closely parallel your targeted market. Harley ruled the dirt tracks for years, making the most effective two wheeled weapon ever slid around a dirt oval. But does this mean anything on the street? Remember that in dirt track racing (up 'til the '70s), shifting was illegal, brakes weren't used and suspension was minimal. And street Harleys seemed to reflect this, having lousy transmissions, poor brakes and sub-standard suspension. With an eye toward making a better sport/touring bike, Guzzi and Dr. John want to return to endurance racing, which they feel will better produce a street bike than the sprint races.

Everything on the Dr. John bike must be made with an eye toward mass production. It does no good to win races on a one-off bike on Sunday and then sell the same old hack on Monday. If all goes according to plan, racing will also help sell the breed. With its newly well restructured U.S. bike division, Moto Guzzi hopes to make significant sales here. Unlike the bad old days of European bikes, Guzzi is prepared to listen to suggestions and make changes. And what better way to make a bike that will sell in America than to have it designed and tested by Americans.

The other side of the coin concerns the dealer network and the functional details on the street bikes. Guzzi has a wide range of bikes from 350cc to 1000cc. They have always had an enthusiastic dealer network, but it needs to be bigger. Changes at the factory level (such as the recent merging of Moto-Guzzi and Benelli into one company) and a shaking-up of the stateside distributor have helped. Now, the factory needs to actually implement the improvements John has developed as well as make detail improvements. The bikes desperately need better switchgear, better suspension, electronic ignitions, lighter flywheels and better carburation and exhaust, just to name a few. They're basically very good machines, the question is whether Guzzi will smooth out the rough edges and make a serious stab at the U.S. market or continue to be content with cult status..